Advanced manufacturing equipments, automatic inspection equipments, high-tech R&D equipments

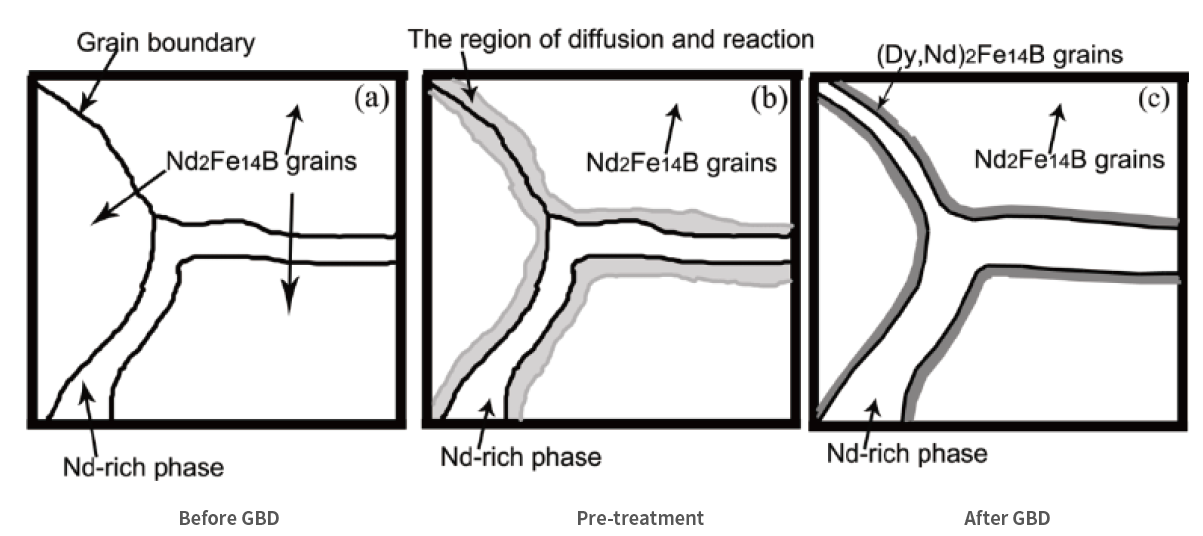

Grain boundary diffusion technology is to form a thin layer of Dy or Tb heavy rare earth on the surface of sintered NdFeB magnet sheet with thickness of 1-9mm by surface coating, magnetron sputtering, vacuum evaporation and electrophoretic deposition.After proper heat treatment and tempering treatment, the intrinsic coercivity of the magnet is greatly improved.It can reduce the use of heavy rare earths material, thereby reduce manufacturing costs. It can also produce high- performance magnet that can't produced by normal processes.

Manual feeding / automatic feeding

Automatic weighing

Workpiece heating

Automatic spraying (A side)

Automatic weighing

On line automatic turning material

Automatic heating

Workpiece heating

Automatic spraying (B side)

Automatic weighing

Unloading / automatic material receiving

Vacuum sintering furnace

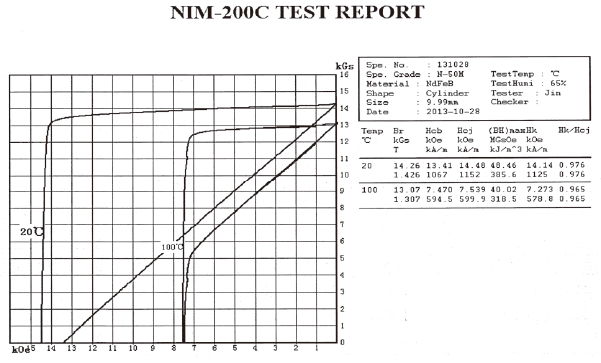

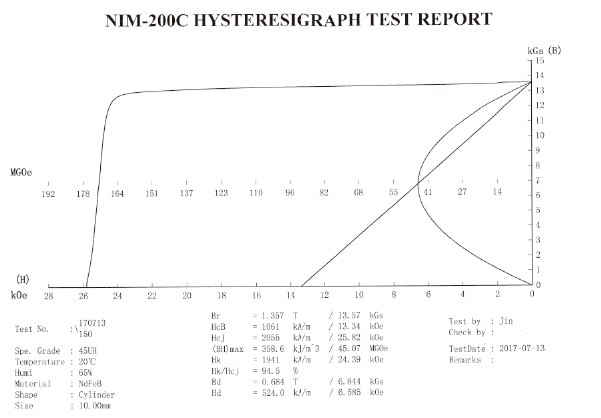

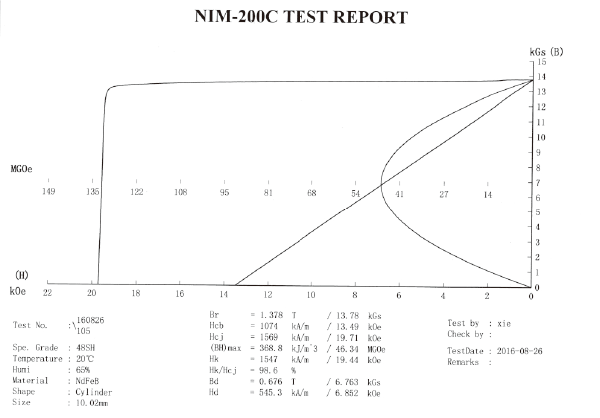

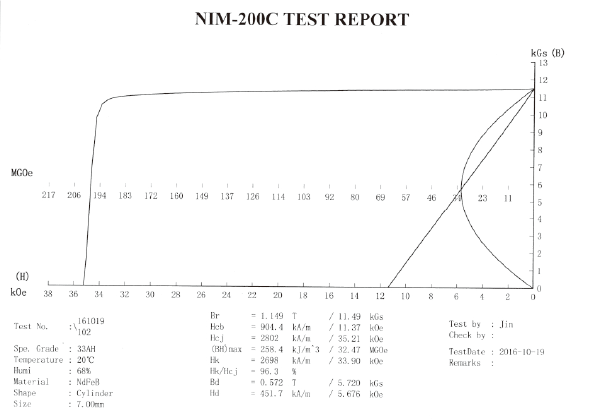

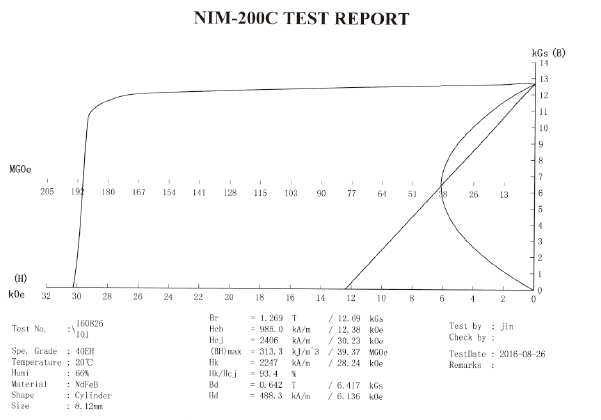

| Content of heavy rare earth in formula | Product thickness(mm) | Increase range of Hcj during grain boundary infiltration of Dy(kOe) | Increase range of Hcj during grain boundary infiltration of Tb(kOe) |

| 0 | <4 | 4~5 | 7~8 |

| 0 | 4~8 | 3~4 | 6~7 |

| >2% | <4 | 3~4 | 6~7 |

| >2% | 4~8 | 2.5~3.5 | 5~6 |